Plywood

I went back and forth on what I wanted to do for walls. From what I’ve seen most people hang steel on the walls in a pole building because it is the fastest and easiest. Due to the weight of drywall and wood steel was going to be my only option for a ceiling. I checked out a couple buildings with steel inside (ceiling + walls) and I just didn’t care for the look or function and I really disliked the tinny sound inside. I also didn’t want to use drywall as you can’t really hang much from it and it is brittle.

At the old house Mark talked me into using BCX (sanded) plywood over CDX (regular) plywood or OSB. His reasoning was that because I was planning on painting the walls BCX would look a lot like drywall and would use a lot less paint than OSB. When we did Jake’s shop bay we did OSB and I recall it taking a LOT more paint than the BCX did at my old house. It was still a tough sell at $18 a sheet vs $8 but I bit the bullet and went for BCX plywood. I was able to haul 40+ sheets at a time in the bed of my truck.

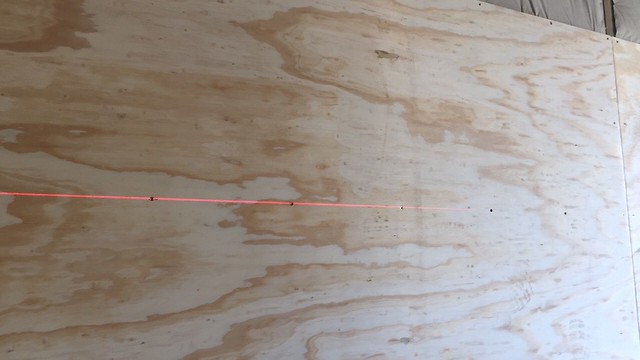

I decided to start hanging plywood in the shop bay as I was worried about tearing the insulation up by accident while working on cars there. You can see below we hung the plywood sideways between the posts to carry the weight and then screwed it to the 2*4s.