Building the FRC’s New Engine: Part 1 Teardown

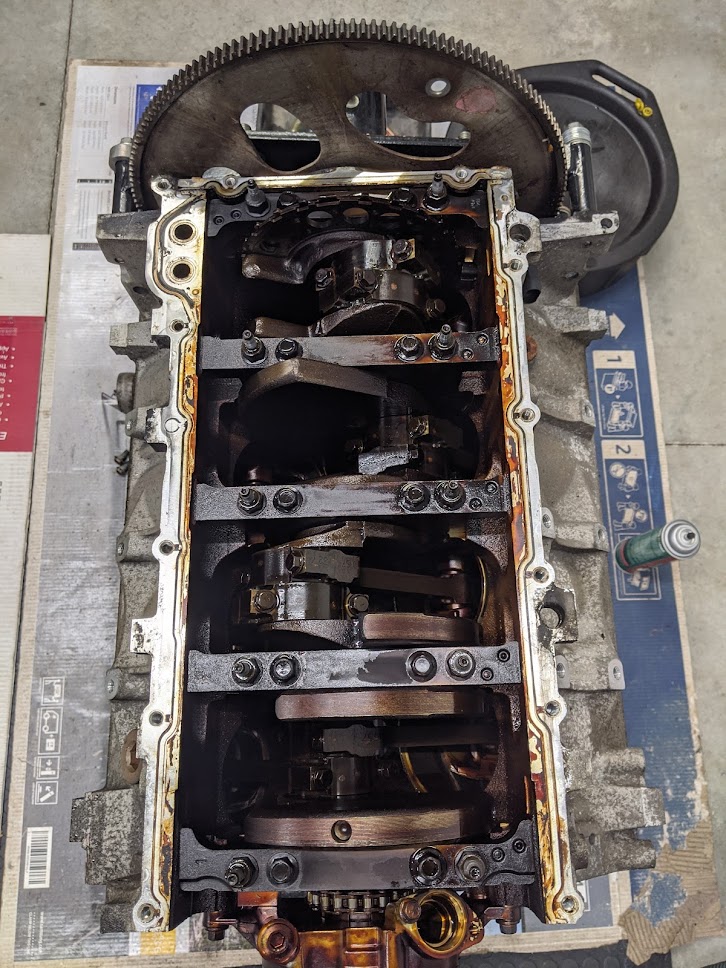

Since setting up this site a little over a year ago I have yet to write a post about engines. Lets change that. First off, originally I built this engine for the IROC but it was largely interchangeable with the LQ9 I had in the FRC. When the LQ9 finally gave up the ghost I put this one in to replace it. These posts (Part 1 and 2) will be very picture heavy to try to show in detail what goes into rebuilding/building an engine.

Back in February 2020 I spotted a running driving 2004 GTO with a 6-speed manual for $3,000 on FB Marketplace. This is by far the cheapest running GTO I’ve ever seen let along one with a manual. I didn’t need it at the time but I knew I’d make money on it and get to keep parts so I jumped on it. I was able to drive it home then it got parked for a few months until I got caught up with other projects.

I parted out the rest of the car keeping the engine, accessories, ECU, and engine harness. It sat on the stand another couple months until the C7 was sold and then I ordered parts to build (performance) and rebuild (maintenance).

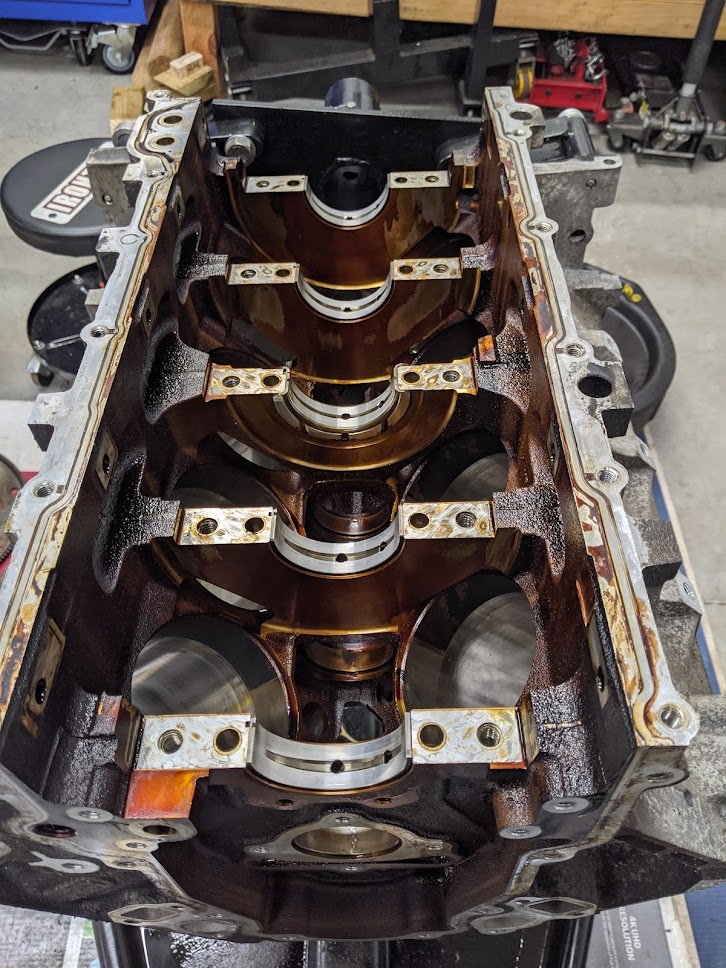

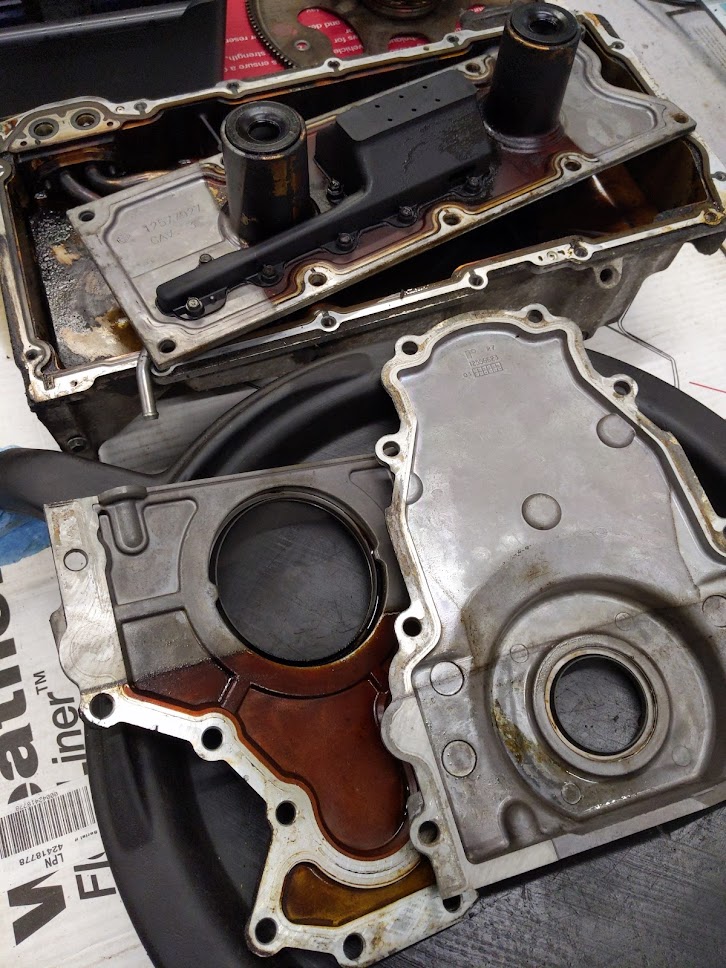

While I was degreasing all the parts I could, I took the engine block, cylinder heads, and valvecovers to a machine shop to have them jet washed and new cam bearings installed as I lack the tools to do so.