Fixing my first transmission

After successfully disassembling and reassembly the Saginaw 4-speed I was feeling pretty good about moving on to something more complicated. This time it wasn’t just for fun or to learn…I had a real problem to solve.

This was T56 #3 in my 1999 Corvette FRC. The first one developed a 4th gear grind within weeks of buying the car. The second one was sourced from a lower mileage wrecked car and worked great but I ultimately swapped it with a “built” trans in my Dad’s Corvette. I was planning on making a lot of power with a supercharger and Dad was happier with a transmission with no issues. While built, this T56 had a slight 5th gear grind when cold. Once the car was driven enough to warm up the transmission it shifted into 5th without issue so I’d just skip 5th gear for the first 10 miles of each drive.

Armed with the confidence of my Saganaw experience along with watching many YouTube videos I felt comfortable digging into it and seeing if I could diagnose the issue and fix it. If I failed the transmission needed to be fixed anyway so I planned to take it to a professional.

I had already diagnosed the issue by this point. Down by the case magnets at the bottom sat what looked like pieces of broken strut keys.

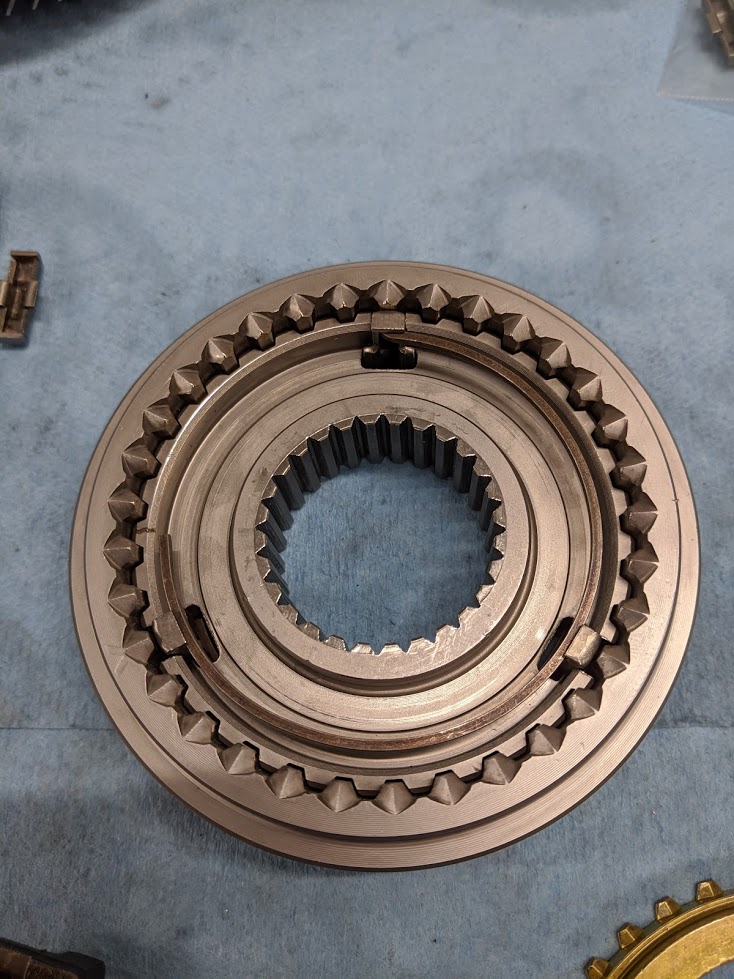

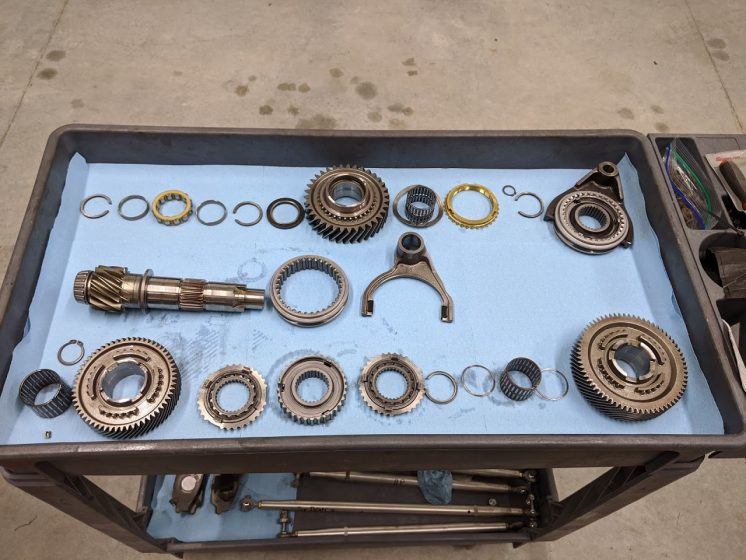

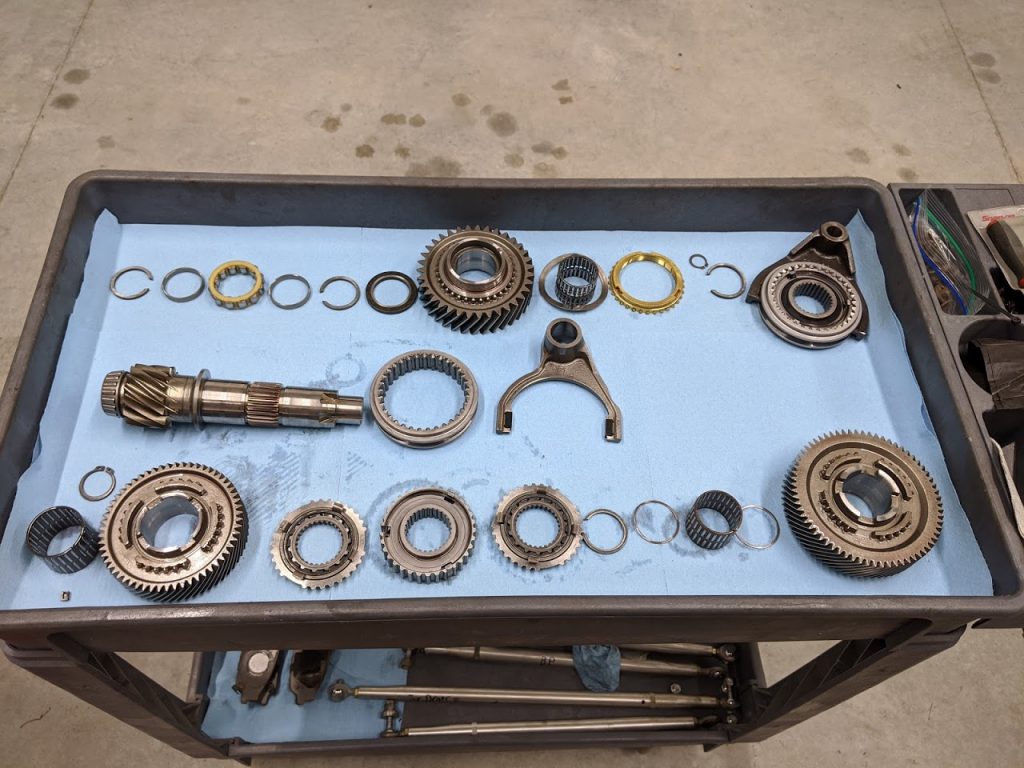

Top row came off the main/output shaft and consists of snap rings, spacers, bearings, reverse gear, reverse syncro assembly and reverse shift fork. The bottom two rows are the counter shaft with 5th and 6th gear along with bearings, snap rings, spacers, the syncro assembly, and shift fork. Note that reverse uses a conventional single cone brass blocker ring, while 5th and 6th use double cone kevlar blocker rings. Only the Corvette, GTO, CTS-V, and SSR had this. The rest of the T56s were single cone 3-6th gear. This means these transmissions are capable of higher RPM shifting.

I’m surprised the transmission worked as well as it did with the damage. Clearly it was not able to apply even force to the blocker ring causing the grind. With everything else looking good I ordered new keys, new springs, and a new set of snap rings as I damaged one of them removing it.

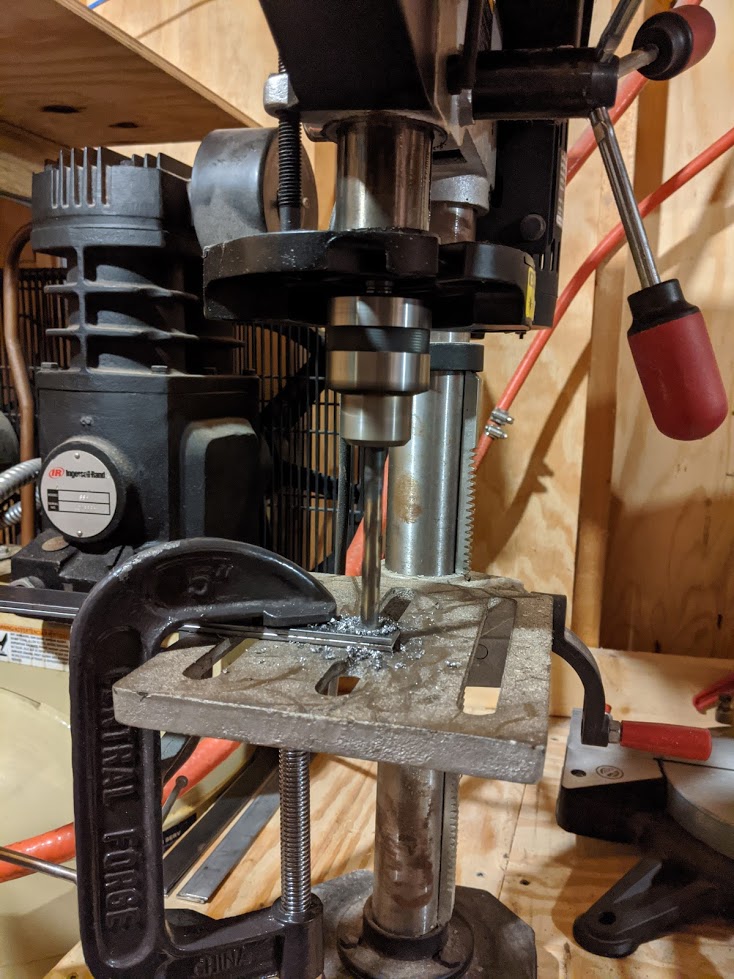

While I was waiting for those parts to come in I ran to Harbor Freight to pick up a set of 3 jaw pullers and some flat stock steel from Farm and Fleet and got to work making a custom gear puller as I needed to remove the press fit driven 5/6 gear from the main shaft in order to get the parts back in the case. They came out in pieces but had to go back in as a unit and the press fit gear was in the way to do so.